Overview

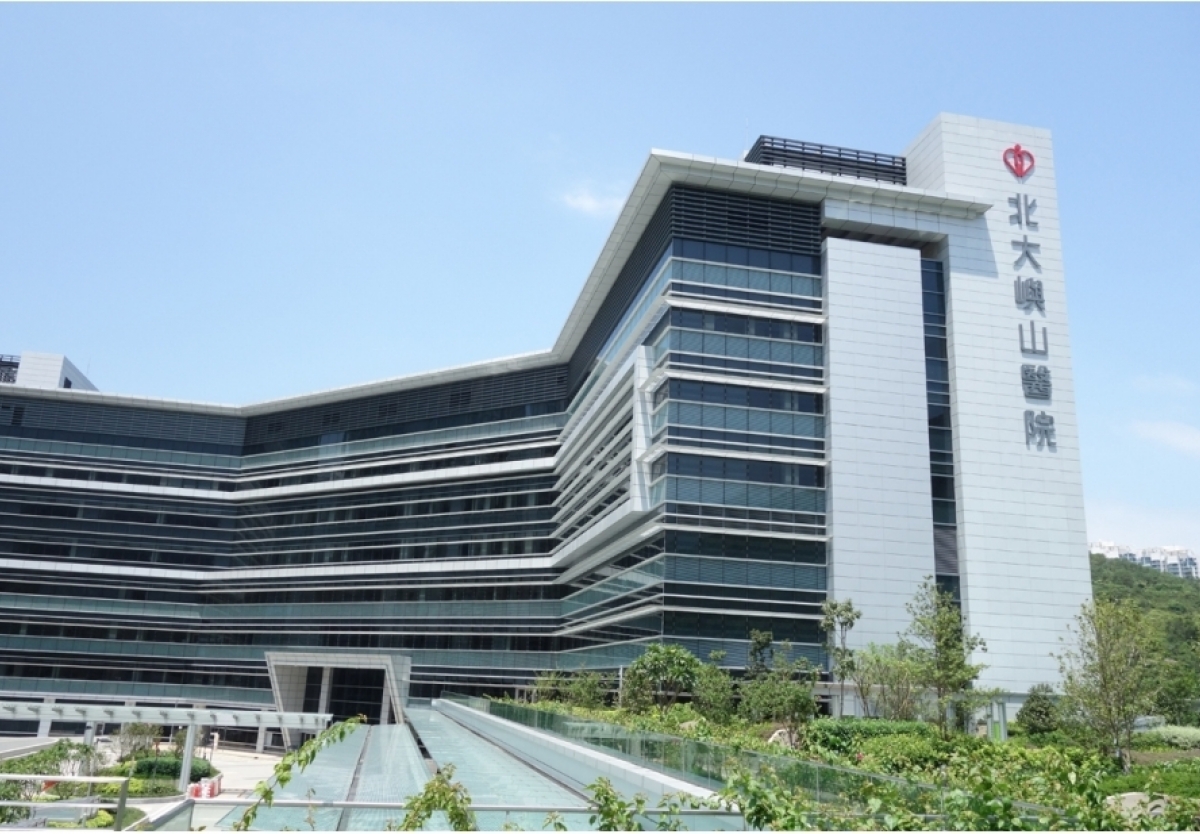

BPS Global Group has successfully completed the largest integrated health care automated distribution centre in Hong Kong for a leading pharmaceutical outsourcing service company in 2017. Our client, one of the leading pharmaceutical outsourcing service companies, made the decision to expand their Infrastructure by relocating its warehouse. Within the new facility, the client looks for process improvement, operational performance boost, and operational cost optimizing. Further enhancement has also been addressed in space utilization and storage capacity. After consulting key stake holders and thorough studying of space requirements, BPS concluded that it is best to utilize automated technology to achieve the clients’ request. Automated technology is very effective in eliminating error-prone human activities such as receiving goods, order picking, order packing and at the same time reduce labor cost.

Aiming to cater the strict requirement and conditions of pharmaceutical storage, this facility has been designed in compliance with the GMP standard and Department of Health (DOH) guideline. With approximately 140,000 sq.ft, the facility is the largest integrated GMP compliant health care automated distribution centre in Hong Kong. It features a series of advanced automation set up and warehouse storage system including the highest carousel storage system in Hong Kong (Over 5 meters), Automated Guided Vehicles (AGVs), mobile racking, high-speed conveyor systems and a temperature controlled cold room with around-the-clock monitoring that covers 6,000 sq.ft. Within the facility, a new GMP compliant clean room with special ventilation system has been built with an aim to provide for secondary package of pharmaceutical products.

In a close collaboration with the BPS team, the client is able to achieve high-efficiency batch picking and batch packaging, significant process improvement and optimal utilization of the warehouse space. Additionally, workforce could be largely reduced as carousels and mobile racking can deliver shorter cycles with higher accuracy and thus achieving long term operation cost reduction. During the implementation of project, our consultant team has established full scope project management and provided innovative solutions to meet client’s stringent requirements in packaging and storage of clean, safe and contaminant-free products. BPS Global Group is proud to have delivered this project under aggressive timelines and budget.

Project Details

Scope of Work

- Design and Build

- Building Services

- Project Management

- Logistics Automation

- High Density Storage Solutions

- Picking Optimisation

Location

- Hong Kong